非官方發佈資料 Unofficial Release

Evolution

of Printing

Industry in

the Era of Digital

Revolution

Dec 29, 2009

PREFACEUM Blogger 網誌編輯組 Feb 5, 2010 The following study was originally a course assignment on the development of printing industry in Hong Kong written by Ms P. Cheng, who is the marketing officer of our company. However, we felt that the idea conveyed in the report worth our serious consideration. It always seems that someone or something is to be blamed for the failure of certain industries or professions under the reapid development of technology. However, some of the players have proved that they survive the change. If the development is irrevocable, the only solution to it is adapte oneself to fit the environment instead of trying to pull back the wheel of history or stop it from rolling foreward. Upon her consent, we contribute this report to the general public with some amendment for complying with the copyright ordianance as an unofficial release of our internal study. The purpose of the report was trying to get some valuable ideas from the failure and success of all market players in the industry in the past few decades for future planning If anyone thinks that he or she is inspired from the study in leading a firm striving to adapte to the ever changing environment in the way as the report describes, we, including the writer, will be delighted to see his or her success. |

|

INDEX 1. INTRODUCTION 2. A BRIEF CHRONOLOGICAL REVIEW OF THE DEVELOPEMNT OF PRINTING TECHNOLOGY 3. THE STRUCTURE AND WORKFLOW OF PRINTING INDUSTRY BEFORE THE DIGITAL REVOLUTION.

4. THE STRUCTURE AND WORKFLOW OF PRINTING INDUSTRY AFTER THE DIGITAL REVOLUTION.

4.1 BACKGROUND

4.2 THE CHANGE OF VERTICAL STRUCTURE OF THE PRINTING INDUSTRY

4.3. THE IMPACT OF DIGITAL REVOLUTION ON THE HORIZONTAL STRUCTURE OF THE INDUSTRY 5 CONCLUSION |

1. INTRODCTION

I started to run a small enterprise dealing with corporate gift items for my family since mid 80s. During that period of time, screen printing (絲印) and hot blocking (熨金) was the most common printing technologies to be employed in making custom made corporate gift items. As we mastered the technical knowhow of artwork production, occasionally we received print job orders from customers who knew that we had the knowledge and technical knowhow to produce the artwork for printing. However, the complicated procedure which was extremely labour intensive and involved many workers or vendors of diversified talents in the prepress process (印前工序) prevented us from heading into the printing industry aggressively. We did hear about the legendary desktop printing introduced by Apple Computer but the quality of printing was far from professional that it was deemed to be applicable in office environment only. The fatal weakness of this frontier technology was its radical high cost. The hardware and software including a desktop, a laser printer, a licensed copy of Pagemaker and Photoshop together would cost hundred thousand Hong Kong Dollars, which was sufficient to buy a small residential flat at that time.

The desktop printing technology kept developing over time. The emergence of Windows version of desktop printing software, though was denounced as inferior, had pushed the cost down significantly. Some printing firm even used pirated copy of software when the idea of intellectual property was not emphasized. We then purchased our first laser printer for the replacement of third party typesetting service. After the imagesetter was invented in late 80s, desktop printing had became the standard equipment of printing industry and invoked a far reaching revolution in printing industry, resulting in a fundamental change in its macro-structure and eco-environment. I personally witnessed the change and some of the issues worth our attention from the management point of view.

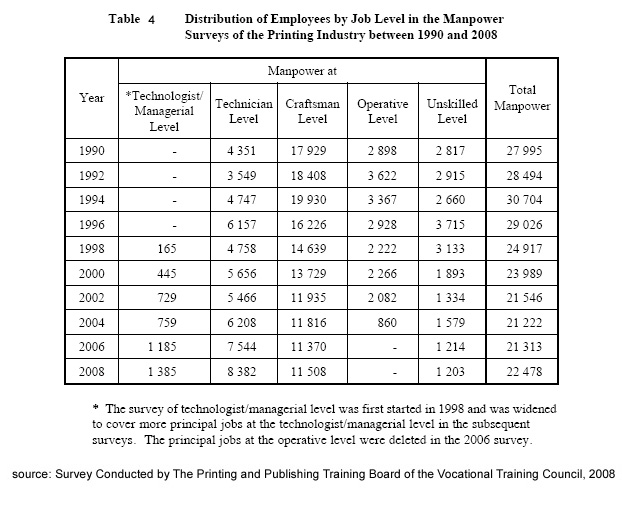

During the period from mid-May to mid-October 2008, The Printing and Publishing Training Board of the Vocational Training Council conducted a survey to collect up-to-date manpower information of the printing and publishing

industries with the assistance of the Census and Statistics Department. Based on the statistics as show in figure 1.1, we can see the change of the profile of employee in the printing industry during the period from 1990 to 2008.

Figure 1.1

It is clear enough to assert that the technical level of workers in this industry has kept increasing in the last twenty years and the job post for craftman or unskilled laborer is decreasing over time. The development of printing technology has invoked a microscopic and macroscopic change in the structure of industry.

2. A BRIEF CHRONOLOGICAL REVIEW OF THE DEVELOPEMNT OF PRINTING TECHNOLOGY

Printing

is one of the 4 great inventions of ancient China. A lot of

technological improvements had been made by different prominent

figures or vendors in the past two thousand years. Among them, the

invention of the “lithography offset” printing technology was the

most significant takeoff and the current digital revolution might

have chance to surpass it in terms of its significance to

communication and impact to our daily life. The following is a brief

chronological illustration of the history of printing technology.

|

The intricate frontispiece of theDiamond Sutra from Tang DynastyChina, AD 868 (British Museum, image courtesy: wikipedia) |

|

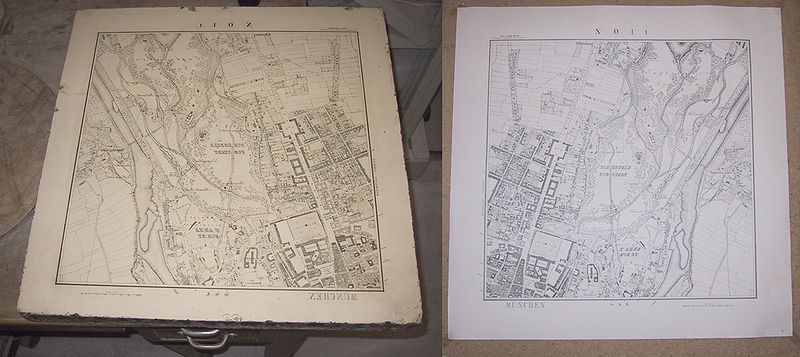

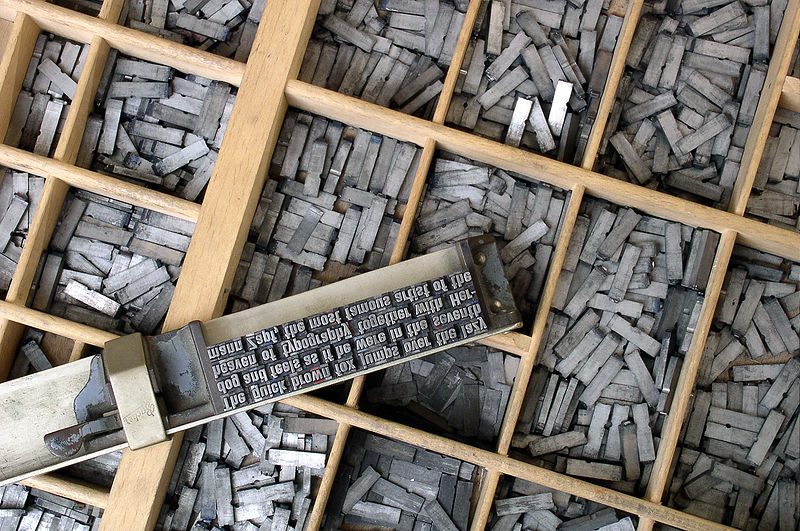

A case of cast metal type pieces and typeset matter in a composing stick. (image courtesy: wikipedia) |

|

Stone

used for lithography print with a Princeton University motif

|

|

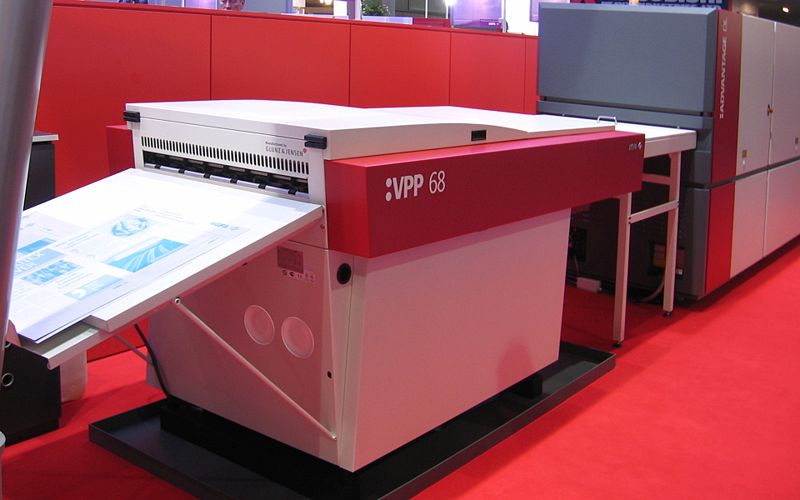

Modern Offset Printing Machine |

|

|

|

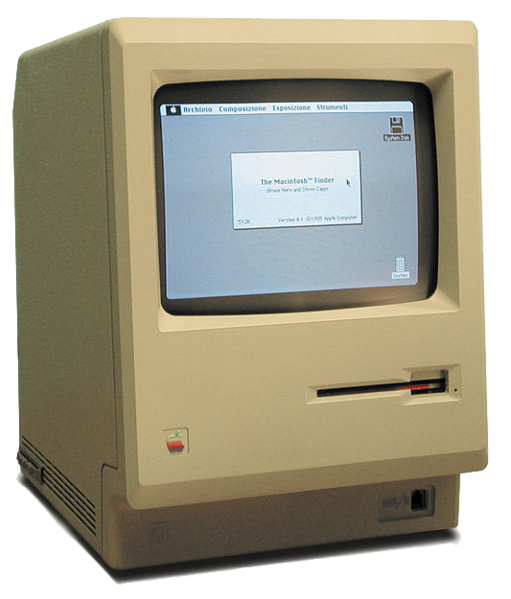

Apple Laser Printer Pro 630 (image courtesy: wikipedia) |

|

Imagesetter (computer to film) (image courtesy: wikipedia)  Plate setter (computer to plate) (image courtesy: wikipedia) |

(Source: http://en.wikipedia.org/wiki/History_of_printing#Digital_press_.281993.29)

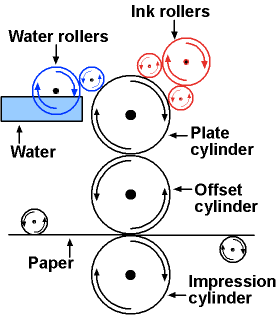

The

first rotary offset lithographic printing press was created in

England and patented in 1875 by Robert Barclay. The first person to

use an offset press to print on paper was most likely American Ira

Washington Rubel in 1903. Roughly at the same time, a German engineer

by the name of Christopher Hermann invented a similar machine when he

accidentally found that the image on the sheet printed by a

transferred image on the rubber blanket was much sharper and clearer

than the direct litho image because the soft rubber was able to press

the image onto the paper better than the hard stone. He soon decided

to build a press which printed every image from the plate to the

blanket and then to the paper. Brothers Charles and Albert Harris

independently observed this process at about the same time and

developed an offset press for the Harris Automatic Press Company soon

after.

Ffig. 2.1 Offset Printing Technology

The advantages of offset printing compared to other printing methods may summarized into the following:

-

Consistent high image quality. Offset printing produces sharp and clean images and type more easily than letterpress printing because the rubber blanket conforms to the texture of the printing surface

-

Quick and easy production of printing plates.

-

Longer printing plate life than on direct litho presses because there is no direct contact between the plate and the printing surface. Properly developed plates running in conjunction with optimized inks and fountain solution may exceed run lengths of a million impressions. and

-

Cost. Offset printing is the cheapest method to produce high quality printing in commercial printing quantities.

On the other hand, there are disadvantages of offset printing compared to other printing methods which include:

-

Slightly inferior image quality compared to rotogravure or photogravure printing.

-

Propensity for anodized aluminum printing plates to become sensitive (due to chemical oxidation) and print in non-image/background areas when developed plates are not cared for properly.

-

Time and cost associated with producing plates and printing press setup. As a result, very small quantity printing jobs are now moving to digital offset machines.

-

Manroland Druckmaschine (Photo courtesy: wikipedia)

Nowadays, offset printing is the most and common form of high-volume commercial printing, due to advantages in quality and efficiency in high-volume jobs. Though there is no detailed breakdown figure about the contribution of offset printing to the GDP, I have reason to assume that it accounts for most the value created by the printing industry in Hong Kong. Take my company as example, over 90% of the print job both in terms of value or physical volume are orders for offset printing. Therefore, I will focus on the offset printing.

3. THE STRUCTURE AND WORKFLOW OF PRINTING INDUSTRY BEFORE THE DIGITAL REVOLUTION.

With

offset printing, the more you print, the less you pay per page,

because most of the price goes into the preparation undergone before

the first sheet of paper is printed and ready for distribution. Any

additional paper print will only cost the client paper price (and

ink), which is very minimal. Featured by its consistent high quality

but very high initial cost, therefore, offset printing is only

justified for large volume of print job. This is an unresolved

problem for both the customer and printer. Furthermore, every print

job involves a prepress process which may cost a lot of time,

material and manpower. A little change in the artwork might a

incurred a cost more or less equal to doing a new job before digital

revolution taking place. Not until the emergence of desktop printing

technology, the printing industry composed of a number of vendors

specialized in a certain process in the vertical workflow of

printing. The following is a brief illustration:

Table 3.1: A Vertical Structure of Printing Industry before Digital Revolution

|

Workflow |

Sub-process |

|

Job Description |

|

Design and Idea |

Idea Script writing Drawing Photograph taking Layout design |

Advertising company Design house Script writer Artist sketcher/illustrator Photographer

|

Need of customer is identified and converted into some ideas for discussion. Finalized idea will be consolidated and turn into primitive production activities like sceipt writing, sketching and photograph taking. |

|

Prepress Process |

Typesetting Origination Proof Reading Darkroom Process:

|

Typesetting company Design house Film making laboratory |

All text must be typeset on bromide paper which will be cut and pasted on a graph paper with photographs and drawings according to the original layout design. Having been confirmed by the customer, the final artwork will be sent to the film maker who are familiar with all kinds of darkroom techniques to add special effect to the artwork as instructed by the designer. At last, the CMYK color separation films were made. Theoretically speaking, all color are reproduced by mixing four color dots on the medium. |

|

Printing Process |

Plate making Blue Print (test print) Prnting Trimming |

Print factory |

This is a relatively straightforward and mechanical step in the whole process. Usually, the cyan plate will be used to make a test print for final proof reading |

|

Post Printing Process |

Lamination, punching, folding or binding |

Special post-printing process service provider |

This is a self-explanatory process |

Both the customer and working people in the field would find that they encountered the following problem:

-

The resulting visual effect of the printing was uncertain especially to layman who had no knowledge in printing.

-

The prepress process was a clumsy, boring and time-consuming iteration process. There was no close preview for the printing effect. Once the final product did not meet the aspiration of the customer, the origination process must be started from the very beginning once again. Disputes between customer and design house over the cost was not uncommon.

-

The designer, as the key person of the artwork production did not have the total control over the final printing product. The darkroom technician always turn down the proposal of the designer and refuse to render the effect as required. It was not uncommon to see open conflict and quarrel between designer and darkroom technician.

These practical problems did hinder the use of high quality offset color printing for SME. A very high degree of division of labour was oberved in the prepress process. Therefore, a print job was regarded as a very serious task requiring very good planning and organization. Most printing in Hong Kong was simple and primitive, usually containing text without or with little graphic in mono just one or two colors. Even in the early 80s, the traditional letterpress (活版印刷) was still in use. Only very limited choices of fonts was available, all the product were almost printed in white wood-free paper.

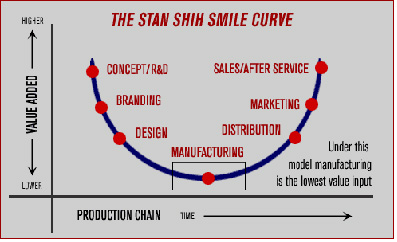

Fig. 3.1 Smile Curve-

High Value Added (image courtesy: Mr. Mark Ng, B.A. Department, Shue Yan University)

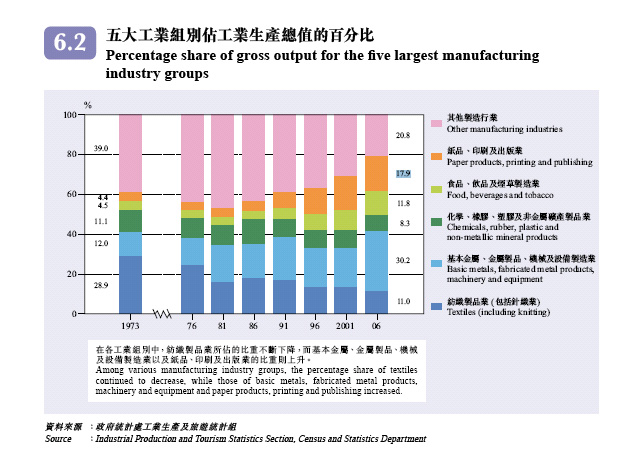

Printing is also a typical industries conforming to the smile curve. (See Fig. 3.1) On the both ends are high value added processes such as marketing, idea, design and technical prepress process while manufacturing (i.e. printing) is the lowest value added service. Therefore, all printing factories tried to capture more profit by extending their service to the two ends. As a matter a fact, quite a lot of small printing factories performed very well in the market in the 70s and 80s, which might be the golden ages for small printing factories in Hong Kong. Even when most of the industries had migrated to Mainland China, the turnover of printing industry remained relatively stable in Hong Kong. (See fig. 3.2 ). The horizontal structure of the printing industry was featured by many small printing factories having a few workers led by the owner as well as manager offering printing services to the general public and a few very big printing firms specializing in the printing of press and books. However, since 90s when the impact of digital revolution has been consolidated, the contribution of printing industry to GDP was increasing but the business environment for small printing factories turned bad.

Fig. 3.2 Percentage share of gross output for the five largest namufacturing indurtry groups

4. THE STRUCTURE AND WORKFLOW OF PRINTING INDUSTRY AFTER THE DIGITAL REVOLUTION.

4.1 BACKGROUND

In 1984, Apple Computer join Adobe and Aldus invoked a digital revolution. Desktop publishing was born and within a year, the combination of the LaserWriter, PostScript and PageMaker saved Apple from a financial crisis due to the down turn of their sales under the keen competition of IBM compatible PC computer, and turned Aldus and Adobe into rich companies. However, the printing quality and capacity of the then digital printing technology was still primitive in comparison with the well developed technology used in the traditional prepress process. Laser printer employs the electrostatic printing technology which use toner instead of ink as the color agent. People only accepted it as office stationery but not professional printing machine.

In 1985, Linotype was the first graphic arts supplier to recognize the value of PostScript and offer an imagesetter with its own PostScript RIP (raster image processor). Other manufacturers like Agfa ad Kodak soon followed and PostScript quickly became the lingua franca of the prepress world. Since then the prepress process began to change rapidly.

4.2 THE CHANGE OF VERTICAL STRUCTURE OF THE PRINTING INDUSTRY

Fig. 4.1 Imagesetter

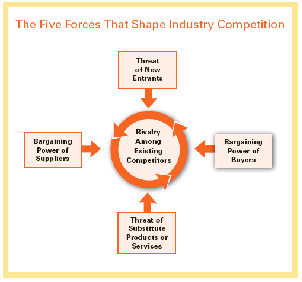

The emergence of the imagesetter was a tragedy to typesetting company and film making laboratory. It was so sudden that some of the firms still purchased new typesetting machine, being unaware of the destructive power to their business. A typesetting firm owner complained to me that he had just purchased a new typesetting machine with all the profit he had earned in the last few years but then became a sack of rubbish in the toilet in just 1 year. Some of the firm invested in the new machine and tried hard to survive in the market. Nevertheless, the income generated from the imagesetter could not match that from the former film making service. Designers grabbed the residual control over the production of artwork from the laboratory technician. They started to render the special effect on their desktop though it was extremely slow on account of the very limited power of computer at that time. Many unprepared typesetting firm and films making laboratories closed down. In 1995 when Microsoft launched Windows 95, which was claimed to be a cheap but close substitute of the expensive Mac OS, there was almost no typesetting companies and traditional film making firm in the market. Some survivors transformed themselves into output bureaus but the job became relatively simple and straightforward which in turn meant that the value added was minimal with respect to their previous business. Soft copies of artwork in certain file format were tendered from designers or customers for outputting directly to CMYK color separation film which was ready for plate making. No value added service was required. The turn over of the whole prepress industry shrink tremendously and a lot of skilled laborer lost their job. Only some of them could be transferred to the new output industry. All that happened because a powerful substitute entered the market which deprived the obsolete service providers of all the bargaining power. It was a perfect illustration of the Porter's five force model. (See Fig. 4.2).

Fig. 4.2 Porter's five force model. (image courtesy: Mr Mark Ng, B.A. Department, Shue Yan University)

On the front end of the printing industry, the artist or designer could have more means to present their idea to the customer. This reduce the uncertainty and the possibility of dispute over the visual effect of the printing product. The newer generation of OS and desktop printing software provided WYSIWYG (what you see is what you get) interface. Hence the design and most of the prepress process were compressed into one single step performed by the artist or designer on the desktop.

Entering the 21 century, the invention of platemaker further reduced the prepress process to minimal. Then the artwork might be directly output to lithographic zinc plate for printing. Output bureau faced the same fate of the former film making laboratory. Though film is still inevitable for some other purposes, the business has been greatly adversely affected since the introduction of plate maker in the printing industry. Now printing industry composes of only two vendors, namely the design house and the print factory. The process can not be said to be a backward or forward vertical integration because the digital revolution has simply extinguished a number of intermediate services providers from the vertical structure of the industry. The following is an illustration of the workflow and structure of the printing industry after the digital revolution.

|

The Vertical Structure of Printing Industry After Digital Revolution |

|||

|

Workflow |

Sub-process |

|

Job Description |

|

Idea, design and prepress process |

Idea Script writing Drawing Photograph taking Layout design Proof reading (preview)

|

Advertising company Design house Script writer Artist sketcher/illustrator Photographer

|

Need of customer is identified and converted into some ideas for discussion. Finalized idea will be consolidated and turn into primitive production activities like sceipt writing, sketching and photograph taking. Then all the textual and graphical content will be put together in the artwork with the artwork production software on the desktop. The intermediate and final artwork will be output to laser or inkjet printer to make a preview proof for the customer's confirmation. Sometimes, for experienced customer, only soft copy of the proof is needed |

|

Printing Process |

Plate making Blue Print (test print) Prnting Trimming |

Print factory |

This is a relatively straightforward and mechanical step in the whole process. Usually, the cyan plate will be used to make a test print for final proof reading |

|

Post Printing Process |

Lamination, punching, folding or binding |

Special post-printing process service provider |

This is a self-explanatory process |

4.3. THE IMPACT OF DIGITAL REVOLUTION ON THE HORIZONTAL STRUCTURE OF THE INDUSTRY

On the front end of the printing industry, the design house now must well master the prepress technique so as to deal with the customer directly. It seems that the initial capital cost of setting up a modern design house is lower than that for setting up a prepress service provider before. However, the increase of the investment in human resources has offset the benefit of saving in capital cost.. The management of design house must do something effective to reduce the turn over rate of employee as the training and replacement of staff is costly. Moreover, the rapid upgrade cycle of software and computer incurred a serious financial burden to the design house. Sometimes, the upgrade of software and hardware is not a actual need but a snob appeal or image building for the firm. Apparently, the initial setup cost is low for design house and the value added for the service is relatively high. However, a lot of hidden cost is not foreseeable. Therefore, in the market, many small design houses or even individual artists working as freelance are competing for very limited orders in the market, on account of the low entry requirement, pushing the price down and sending confusing market information to the customers. There is almost no fair market rate for the artwork production or graphic design service.

To cope with this problem, as a design service provider and printing agent, we tried to lay down a relatively objective standard as a reference for calculating the service charge since 2000. In the first place, we isolate ordinary production from creative design service which requires subject judgment. All ordinary production activities are broken down and clearly defined so as to make them measurable. This process of formalization and normalization of artwork production and output service seems to be working well. In dealing with creative services, the problem still persists. We find that customers in Hong Kong are actually not prepared to pay for the “creative service”, or they simply do not recognize the value of creative service. As a result, the turn over rate of design house or printing agent is high in the context of Hong Kong. The statistics about the number of establishment done by the government does not tell the true story of the issue. In the second place, we carefully chose our trading partners and monitored the market price frequently. We set up a quality standard, mainly for checking the color accuracy for the products supplied from our vendors, especially those in mainland China who adopted a loose sense of quality management.

Fig. 4.3 One Stop Online Printing

(Image courtesy: Screen capture from eprint under fair use)

On the rear end of the work flow, I do not think that there was a observable horizontal integration of printing factories. Big factories exist for their own sake because they mainly serve mass media and their order is relatively stable. As printing process is actually a low value added process, their rival in mainland China had capture a large amount of order. Other small to medium size printing factories were competing in a way that all profit was eroded for the ever descending price in the market. A series of economic crisis caused by the internet bubble and SARS during the period from 2000 to 2003 had smashed the industry heavily. A namecard printing factory then tried a very smart method to capture more orders from customers. It extended its service vertically to the upward side by accepting print order directly from customers at extremely low price. This was made possible by two innovative approaches. At first, instead of offering custom design service, it created thousands of name-card template ready for use of the customer free of charge and printed the name-cards of ten or more customers together in a single print job. These clever arrangements reduce the per capita cost of printing for every customer. Soon other trading rivals were aware of its success and copy their approaches. However, the management of both the marketing and production activity must be improved because the profit could only be attained on condition that there were sufficient orders for a single print job. This was not just a price war but also a war of corporate management. After a few years, only a few market leaders survived in the market, most of the small to medium size printing factories close down or running in a misery situation. To reduce the possibility of dispute over the quality of printing, all these successful printing factories had done a lot of work to normalize and formalize the work flow from accepting order to delivery of products. Fig. 4.3 is a screen capture of the web page of a prominent printing factory in Kwun Tong. From there a customer may obtain thorough information about the requirement of the material he must tender and the specification of the final product he intend to order. For a certain period of time, they tried to offer customer design service but seemed to fail for lacking competent personnel.

5. CONCLUSION

The digital revolution triggered a slaughter in the printing industry. The vertical structure was reduced to two vendors, namely the design house and printing factories. However, nobody is safe in the digital era when everything is changed at a much faster speed than in the previous time. Paper media is nor under the challenge of electronic media. Though it seems that the paperless world is still remote but nobody can deny the possibility that the next revolution will take place soon in just a few years or few months. It can be foreseen that the demand for design service will continue to be exist in the market but there will be more challenges for the manager of printing factories in the light of the ever increasing vow for environmental protection and increasing use of internet information service.

General Reference:

1. http://en.wikipedia.org/wiki/Printing

2. http://en.wikipedia.org/wiki/Print

3. http://en.wikipedia.org/wiki/Printing_press

4. http://en.wikipedia.org/wiki/Offset_printing

5. http://bx.businessweek.com/digitizing-print/view?url=http://en.wikipedia.org/wiki/Digital_printing

6. http://en.wikipedia.org/wiki/Computer_to_plate

7. Hong Kong Digest various editions

8. VTC <http://www.vtc.edu.hk/it/pptb/>

9. http://www.answers.com/topic/printmaking